Lifting equipment inspection is an essential measure for maintaining safety and ensuring smooth operations across various industrial sectors. A structured and routinely performed inspection process not only helps prevent workplace accidents, but also ensures that all lifting equipment operates in accordance with established standards.

This article provides a comprehensive overview of lifting equipment inspection, covering its definition, objectives, and processes, as well as the types of inspections and practical tips for selecting the right inspection service provider.

These recommendations are supported by the experience and standards implemented by Indo Veritas.

What Is Lifting Equipment Inspection?

Definition and Objectives

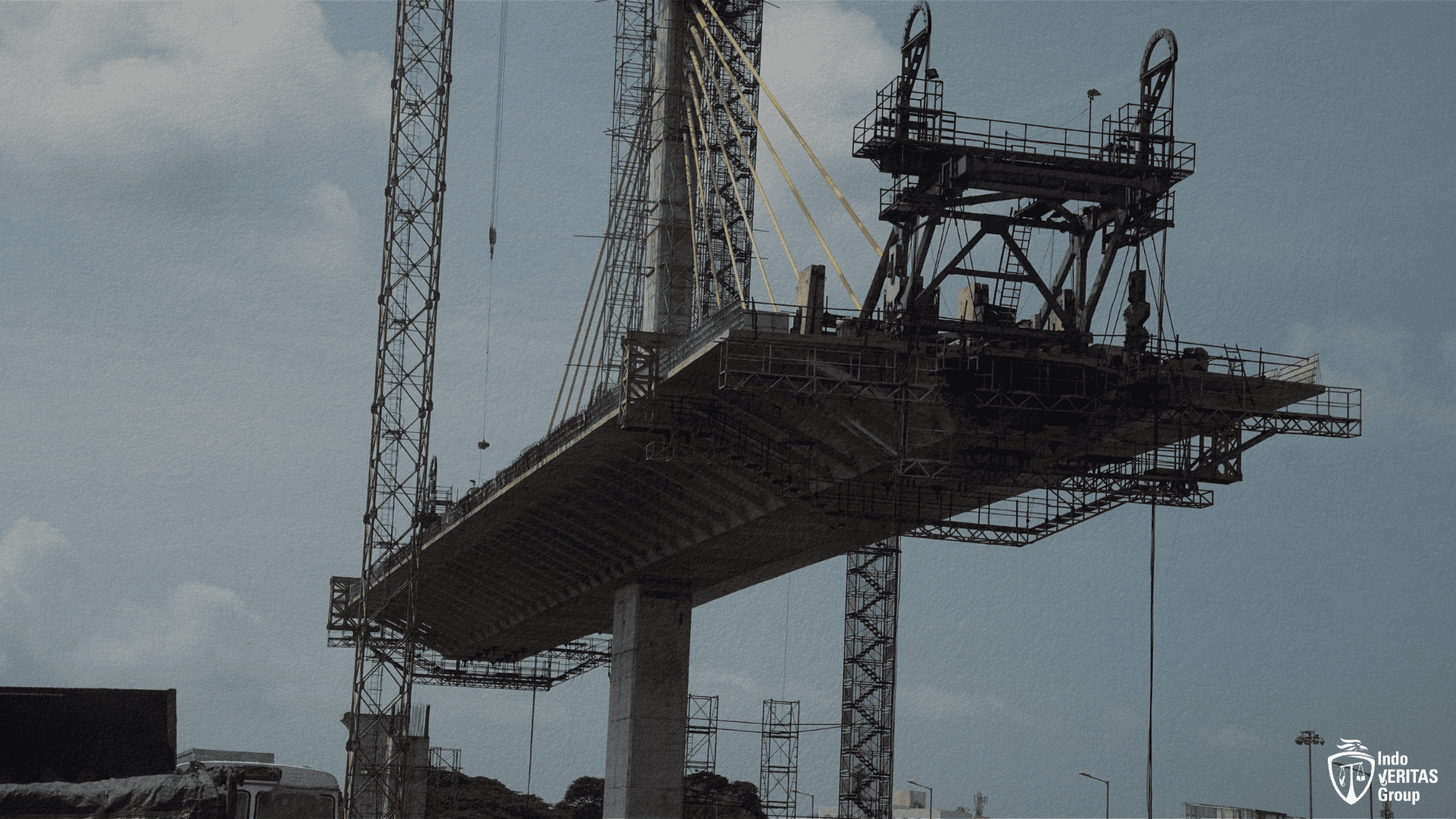

Lifting equipment inspection is a planned evaluation of all tools used in lifting operations, such as cranes, chain slings, and other lifting devices.

- Main Objectives:

- To ensure operational safety by detecting potential damage or wear at an early stage.

- To maintain equipment reliability so it can perform optimally and efficiently.

- To ensure compliance with national and international regulations and industry standards.

Inspection Process and Applicable Standards

The inspection process includes visual examinations, functional testing, and load testing conducted at regular intervals. Commonly referenced standards include:

- LOLER (Lifting Operations and Lifting Equipment Regulations): Provides fundamental guidelines for safe lifting operations.

- ASME B30: An American standard governing the use and testing of lifting equipment.

- SNI (Indonesian National Standard): Local regulations ensuring lifting equipment meets Indonesia’s safety requirements.

In accordance with these standards, inspections are carried out by certified technicians using advanced inspection tools to ensure accurate and reliable results.

Benefits of Lifting Equipment Inspection

1. Ensuring Operational Safety

Routine inspections serve as a preventive measure against potential workplace accidents. By thoroughly checking each component, structural weaknesses can be identified before functional failure occurs, protecting operators and the surrounding work environment.

2. Damage Prevention and Preventive Maintenance

Early detection of damage or wear allows timely repair or replacement, reducing the risk of major failures and operational downtime. This approach also helps minimize long-term maintenance and repair costs.

3. Compliance with Regulations and Industry Standards

Through regular inspections, companies can ensure that their lifting equipment consistently meets safety requirements. Compliance not only helps avoid regulatory penalties, but also enhances the company’s reputation in terms of occupational safety and reliability.

Types of Lifting Equipment Inspection

1. Non-Destructive Testing (NDT)

NDT methods allow defects in equipment to be detected without causing damage. Techniques such as Magnetic Particle Testing (MPT) and Dye Penetrant Testing (DPT) are highly effective for identifying cracks, surface defects, and material deformation.

2. Load Testing

Load testing verifies that lifting equipment can safely withstand loads in accordance with its Working Load Limit (WLL). This test is performed by gradually applying a specified load and observing the equipment’s operational behavior.

3. Lifting, Load Control & Height Safety (LC HSE) Inspection

This comprehensive inspection covers not only lifting equipment, but also load control systems and working-at-height safety aspects. The service ensures that all components involved in lifting operations function safely, efficiently, and in an integrated manner.

4. Installation & Maintenance Inspection

This type of inspection focuses on evaluating installation conditions and routine maintenance practices. Its objective is to ensure that equipment is installed correctly and maintained according to schedule, thereby extending its service life.

5. Kemnaker Anchor Point Inspection (Uji Riksa Angkur)

This inspection evaluates anchor points in accordance with standards set by the Indonesian Ministry of Manpower (Kemnaker). It is critical for ensuring that anchor points used in working-at-height areas are safe and compliant with regulations.

6. Kemnaker Lifting Appliance Inspection (Uji Riksa Pesawat Angkat Angkut)

This inspection assesses the entire lifting system, including cranes and lifting appliances, to obtain official certification from Kemnaker confirming that the equipment is safe for heavy-duty operations.

How to Choose the Right Lifting Equipment Inspection Service

1. Evaluate the Service Provider’s Credibility

Select an inspection provider with a proven track record and strong references from reputable clients. The provider’s credibility directly affects the accuracy and reliability of inspection results.

2. Certification and Operational Standards

Ensure the service provider complies with relevant national and international standards and holds appropriate certifications. These operational standards guarantee that inspections are carried out using safe and recognized procedures.

3. Inspection Technology and Methodology

Choose a provider that utilizes modern inspection technology and proven methodologies. Advanced inspection tools deliver more precise, consistent, and trustworthy results.

Indo Veritas is widely recognized as a professional and certified provider of lifting equipment inspection services. Backed by extensive experience and a team of competent experts, Indo Veritas delivers comprehensive inspection solutions in full compliance with industry standards.

Do not compromise on operational safety. Ensure your lifting equipment remains in optimal condition through professional inspection services. Contact Indo Veritas today for consultation, service proposals, and inspection solutions tailored to your industry requirements.